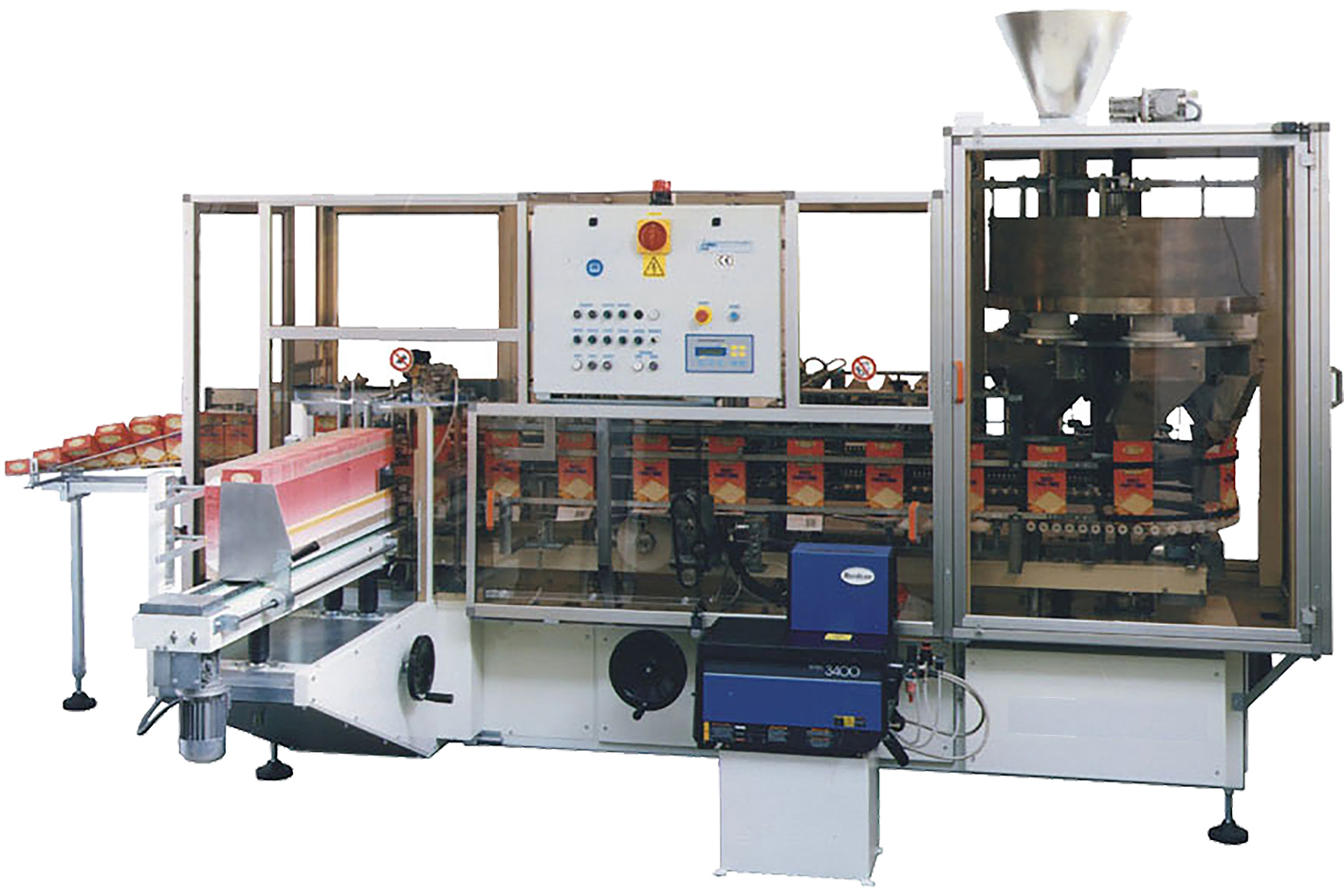

TEKA V6

Vertical Cartoner

- Products: Short pasta, legumes, flour, sugar, rice, chocolates, snacks, legumes, cereals, frozen foods, dried fruits, pet food, non-food items, couscous

- Speed: 120 packs/min

- Capacity: from 100 g to 1000 g

- Power: 11 kW

- Air consumption: (at 6 bar) per cycle NI 47

- Pressure: Operating pressure 6 bar

- Voltage: Three-phase, 400 V

- Frequency: 50 Hz

- Control voltage: 24 V AC / 24 V DC

- Electrical absorption: 40 A

TEKA V6 MODEL DESCRIPTION

The vertical cartoner model TEKA V6 has been designed for the forming, filling, and automatic sealing of pre-glued cardboard cartons along the side corresponding to the height dimension. The cartons are filled automatically using a volumetric doser.

The machine consists of a painted steel supporting frame to which all functional groups are attached. The machine operates in continuous motion, with the possibility to vary the production speed via an inverter. Carton forming and sealing are controlled by a gearbox and an electric motor.

The side magazine is made of painted steel, while the components in contact with the carton are made of polished aluminum, chrome-plated steel, and stainless steel. Carton coding is carried out on the outer flap using a pressure embossing coder.

A vibrating table is located in the filling area to help settle the product. The carton exits via an in-line dual-belt conveyor.

COMBINATIONS

VOLUMETRIC FILLER

The volumetric filler is suitable for dosing granular products. The device consists of six dosing cups with electronic volume adjustment and can be paired with a feedback system with weight control. It guarantees high dosing performance: it is equipped with a screw feeder with brushless motorization for better precision. It allows easy accessibility for maintenance and cleaning. The speed reaches 130 doses per minute, the electrical voltage is 400 V, and the installed power is 2 kW.